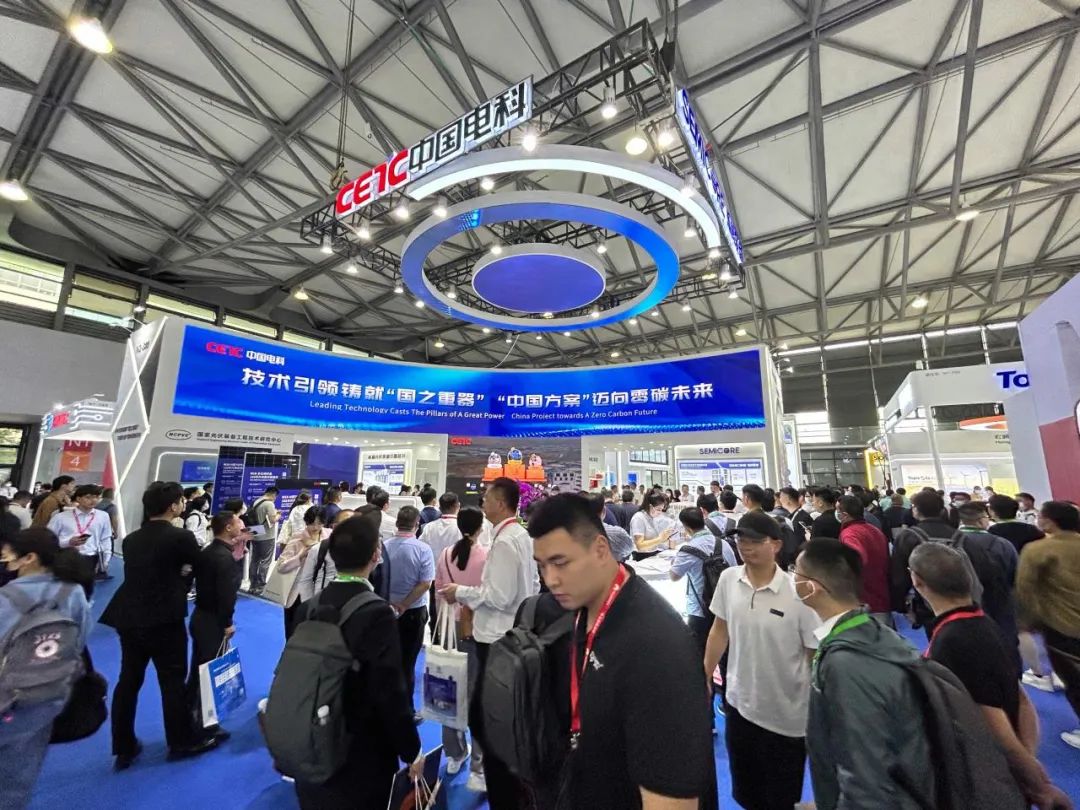

On May 24, SNEC's 16th (2023) International Solar Photovoltaic and Smart Energy Conference and Exhibition opened in Shanghai. CETC brought high-end photovoltaic equipment, intelligent manufacturing system solutions, overseas construction solutions, etc. to the exhibition, comprehensively displaying the practical achievements of "green" and "new" climbing, science and technology to support the high-quality development of the photovoltaic industry.

Focus on cutting-edge technology, high-end equipment"Iterative Upgrade"

In the crowded booth, CETC self-developed domestic first graphite boat/quartz boat dry cleaning equipment for photovoltaics, the newly released TOPCon laser SE boron expansion equipment, laser printing equipment and other products became the focus of attention of the audience.

The first dry cleaning equipment for graphite/quartz boats for photovoltaics in China

"It looks like a 'big house' from afar, but its actual efficacy is extraordinary. With this equipment, the cleaning and boat plating process can be completed at once." Technical experts said that CETC independently developed dry cleaning equipment for graphite boats/quartz boats for photovoltaics, the first of its kind in China, can greatly improve the flow rate and significantly reduce production and labour costs. Facing plasma-enhanced chemical vapour deposition and low-pressure chemical vapour deposition processes, CETC independently developed vertical platform equipment, which breaks through the traditional structure and adopts the patented technology of metal chamber and online cleaning chamber, has the advantages of large capacity and easy maintenance.

TOPCon laser SE boron expansion equipment, laser printing equipment

At the exhibition site, CEC released two latest equipment, TOPCon laser SE boron expansion equipment and laser printing equipment. Among them, TOPCon laser SE boron expansion equipment improves the boron doping effect of TOPCon cells by laser, and helps to increase the photoelectric conversion efficiency of cells by 0.25% and above stably, and the technology reaches the leading level in China. "Laser printing equipment for the first time proposed to contactless processing to achieve the solar cells, PERC cells, TOPCon cells, HJT cells, silver paste laser printing", the site technical experts explained. The equipment can increase the cell photoelectric conversion efficiency by 0.3%-0.5%, and compared to the traditional contact processing method, the contactless processing does not directly touch the product, which reduces the probability of product breakage, scratch, pollution and hidden cracks, and further improves the production efficiency.

As the "national team" of high-end electronic manufacturing equipment in China, in recent years, relying on its profound accumulation in the field of integrated circuit equipment, CEC has continued to promote product iteration and upgrade and industrialization applications. Up to now, it has launched the first domestic ingot casting furnace, tubular PECVD, diffusion furnace, plasma etching machine and other high-end equipment, serving 80% of domestic photovoltaic enterprises, and the market share of its fist product PECVD equipment is the first in the industry. Grasping the development trend of the industry, around the TOPCon battery field, CEC has independently developed LPCVD, boron diffusion, PEOCVD equipment and graphite boat/quartz boat dry etching machine. In the field of HJT batteries, CECC has independently developed flat PECVD and flat PVD equipment, as well as atomic layer deposition equipment and continuous magnetron sputtering equipment for calcium titanium ore batteries, continuously empowering the development of the industry with high-end equipment.

Building a "China Solution" towards a "Zero Carbon Future"

Cooperating with Turkey's Kalyon Group to build a whole industrial chain of photovoltaic industry park project to achieve full production, exploring a new industrial business model of equipment and new energy sector in India, and jointly building a "China-Egypt Renewable Energy National Joint Laboratory" with Egypt's Institute of Scientific Research and Technology ...... With hardcore technology, CEC insists on the "equipment + process + service" model to create "Chinese solutions", precisely matching the needs of users and erecting a "Chinese name card" of high-end equipment for the whole line of global photovoltaic.

Panoramic view of Turkey's first PV whole industry chain industrial park project

At the exhibition, CEC launched "tailor-made" solar PV production line turnkey services and intelligent manufacturing integration solutions for customers at home and abroad, using intelligent systems to create intelligent manufacturing factories for customers and achieve rapid customisation.

Intelligent three-dimensional storage systems

In response to the painful problems of low utilization of storage space, low operational efficiency and difficult information traceability in the photovoltaic industry, CEC also launched customized intelligent three-dimensional storage solutions to significantly improve storage capacity and operational efficiency.

In the future, CEC will continue to grasp the development trend of the industry, continue to promote the iterative upgrading of equipment and system capabilities, and contribute more scientific and technological power to green development.

--From / Group company WeChat public website